Understanding the Difference Between Wire Harnesses & Cable Assemblies

Without the wires and cables that transmit power and data to and from many of our electrical devices, our world would be a much different place, one seemingly stuck in the 1800s. No TV or radios. No Internet or phones. No cars or planes. No machines to mass-produce the many products we get at our local department stores.

While wires and cables are essential components behind many of the conveniences we experience today, they are often grouped together into wire harnesses and cable assemblies, which are intentional bundles of those components that further enhance performance, organization, and durability. Both are highly customizable, offering a wide variety of sizes, materials, shapes, and colors.

For over 35 years, CAI has been a global leader in cable assembly and wire harness manufacturing, offering expert craftsmanship and guidance through every step, from design to delivery, for industries of all shapes and sizes. Start a conversation with us today about your unique electrical needs.

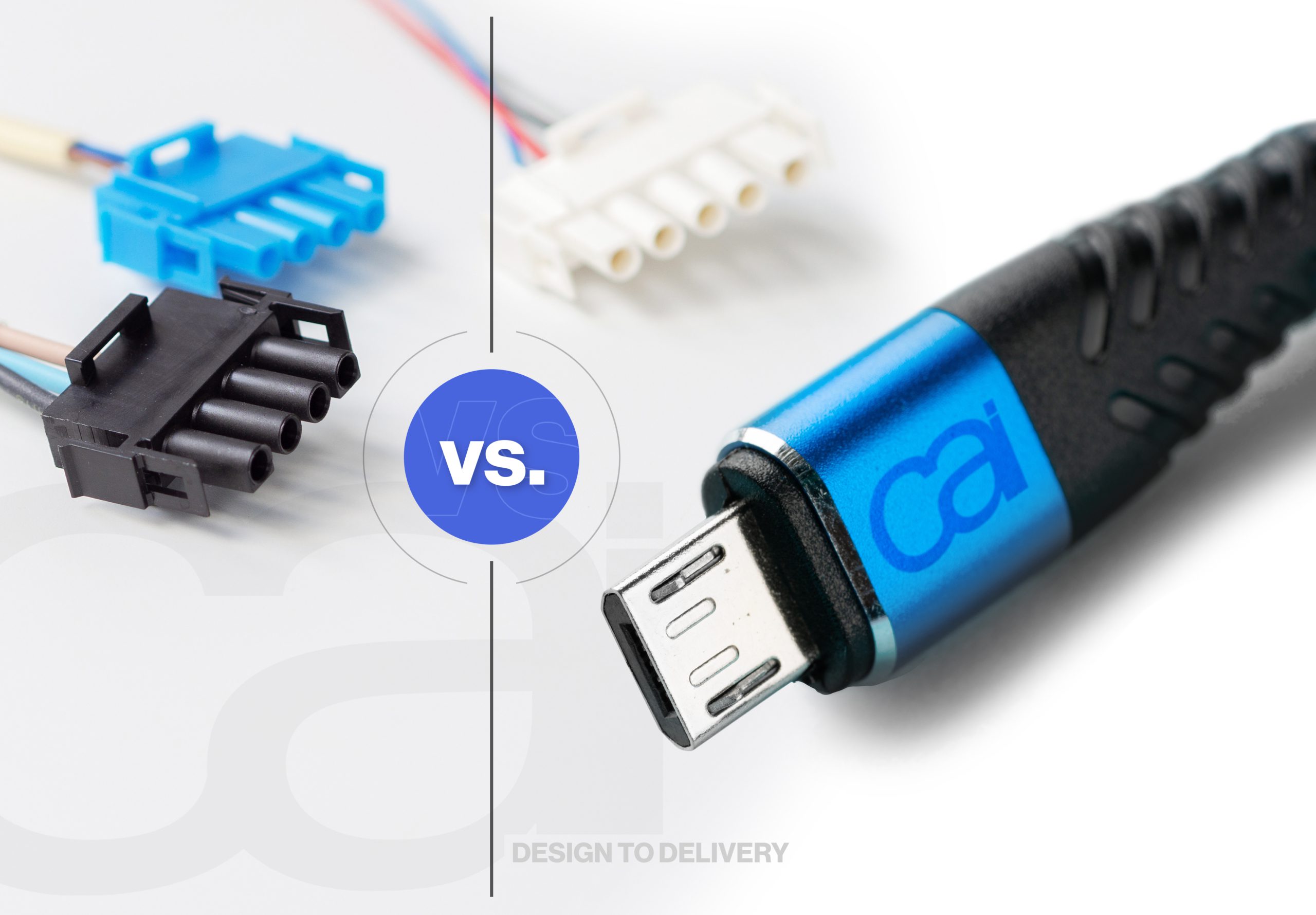

Used in a wide variety of applications across every industry including automotive, medical, industrial, aerospace, telecommunications, and military, cable assemblies and wire harnesses may be similar in purpose and are terms sometimes mistakenly used interchangeably, but they are far from being the same. While it’s easy to tell a wire harness from a cable assembly just by looking at them, there are also a number of other differences.

Knowing these differences will help you choose the best electrical solutions for your product because its success often depends on matching the right harness or assembly with the specifications of its intended application.

Wire Harnesses

Wire harnesses feature a number of wires bundled into one cohesive unit that connects several points or circuits with multiple breakouts — each serving separate functions with separate terminations and organized for easy routing through a system or box build.

Each wire in a harness consists of a conductor (e.g. copper) and has its own exterior covering — heat-shrink tubing or a jacket — typically made from a thermoset or thermoplastic material and colored for easier organization and handling. This jacket doesn’t normally offer much protection for the conductor itself, hence why wires and wire harnesses are better for applications where environmental threats are at a minimum and a product’s housing itself provides the protection.

Harnesses are typically held together using ties or some type of protective sleeving to help protect against external conditions such as moisture and extreme temperatures. Unlike cable assemblies, harnesses are usually found inside products, such as engines, computers, automation control systems, medical equipment, appliances, machinery, and HVAC systems.

Cable Assemblies

Appearing as one thick cable, a cable assembly consists of multiple wires or cables bundled together and encased in an additional (typically thermoplastic or vinyl) sheath, or sleeve, for added protection and durability. Cable assemblies are designed mostly for outdoor applications, and other demanding environments involving threats like water, temperature, chemicals, and friction/vibration. Their added resilience also makes them ideal for when wires and cables must be routed around obstacles. Furthermore, additional processes such as overmolding offer enhanced protection.

Rather than featuring several pathways and ends, a cable assembly creates a singular path from one point/circuit to another, so it generally has only two ends with a connector/plug on each end. Unlike wire harnesses, cable assemblies aren’t typically enclosed but rather operate outside of or between electronic devices such as flat panel displays, automotive electronic systems, integrated cockpit systems, LED-lit products, and more. While assembled cables offer longer lifespans and enhanced performance under harsher conditions, they can be oversized and heavier than harnesses. Their added shielding also can make them costlier.

In summary, here are the four top differences between wire harnesses and cable assemblies:

1. Physical Characteristics

The most noticeable difference between a wire harness and a cable assembly is their physical attributes. While a cable assembly appears as one long, thick, snake-like structure with two ends, a wire harness has visible, bundled wires, is typically lighter and smaller, and features several pathways and connection points which often make it look spider-like, with multiple “legs.”

2. Typical Environments

Because harnesses are designed more for efficient organization, they provide minimal protection of wires and, therefore, are generally reserved for use indoors and within already enclosed products. Offering greater resistance to external threats, cable assemblies are more ideal for outdoor environments or harsher indoor ones such as those in industrial and construction settings.

3. Types of Applications

Wire harnesses are popular in many of the household products we use every day, from refrigerators and microwaves to computers and televisions, as well as essential vehicles such as automobiles. For products and industries which require more durable, high-performing solutions and higher speed transfers, such as those required for the military, medical, and aerospace industries, cable assemblies are the more reliable, efficient choice.

4. Main Purposes

The primary functions of a wire harness are to guard people, objects, and other external elements from the dangers of electricity; create optimal pathways for power and data to ensure the reliable performance of the device it’s serving; and provide a more organized, simplified system for easier installation and maintenance.

Cable assemblies are designed to do all of that, plus better protect internal components from typically harsher outside threats such as moisture, chemicals, and electromagnetic interference.

Hopefully you now have a better understanding of wire harnesses or cable assemblies and which might be the better choice for your electrical project. Not only can the pros at CAI help you make the best decisions, but they also have the processes and optimal solutions to bring your custom product to life. Whatever your volume or specifications, CAI has the experience and expertise you can trust. Contact us today with your unique electrical needs.