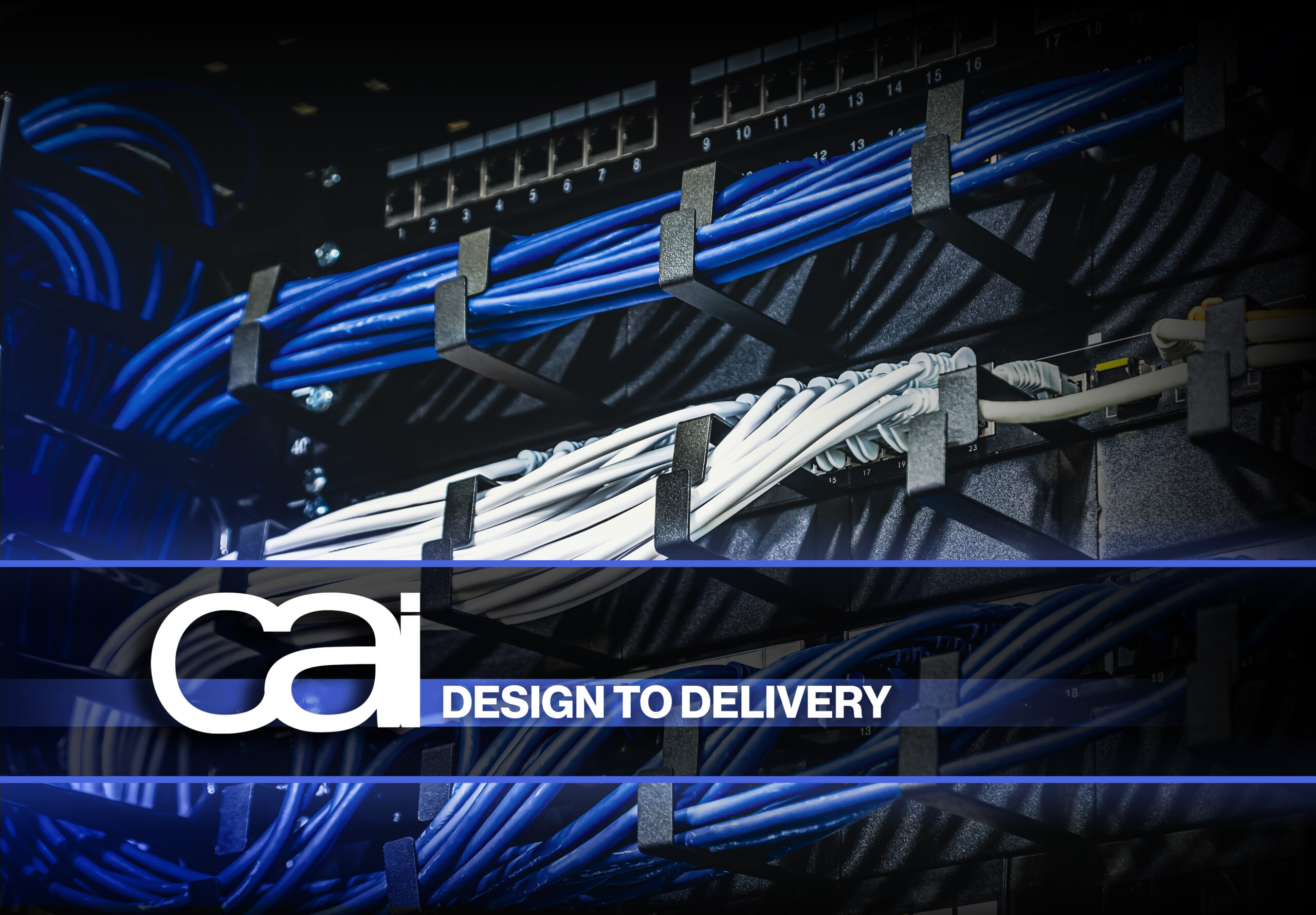

Quality Cable Management is a Must for a Safe, Efficient, & Attractive Environment

With all the technology, screens, vehicles, and machines we use in our everyday lives comes the cables and wires needed to power them and feed them data. Because they’re often numerous, long, and covering a sizable area between electrical sources and devices, these cables and wires can pose a number of problems if they’re not managed correctly, including tangling, tripping, wear/abrasion, disconnections, latency, fire hazards, and visual nightmares.

Effective cable management — the practice of organizing electrical cables in an efficient, optimal manner — starts with the right types and lengths of cable for an application and environment. It also involves employing the best techniques such as routing, labeling, and the use of cable ties, trays, stand-offs, and raceways to ensure continual safety, pleasing aesthetics, easy accessibility, and reliable cable performance.

From the home and office to the factory floor, different settings and applications present different challenges when it comes to proper cable management. Each space is unique and requires unique solutions that often only expert design, direction, and installation can provide.

At CAI, we design and manufacture all volumes of custom electrical cable assemblies and wire harnesses. We offer expert cable management solutions — including custom overmolding, optimal materials, connectors, and lengths of cable — to ensure a safe, efficient, and aesthetically pleasing environment. Reach out to us today about your needs and specific applications.

3 Top Benefits of Effective Cable Management

There are several advantages that good cable management offers, including these top three:

1. Enhanced Safety

Loose and tangled wires and cables strewn across the room or hanging from the ceiling can take up a lot of precious space, but the more worrisome issue is the potential safety risks they create, the top among them being increased odds of tripping accidents. Successfully routing and securing cables reduces clutter which is especially important in the workplace where such an incident can result in everything from missed work days to lawsuits.

Poor cable management can also leave cables vulnerable to significant, consistent movement and strain that can lead to compromised conductors, shorts, and possibly electrical shock or hotspots leading to combustion fires. Furthermore, it can inhibit airflow and cooling which could result in extreme, damaging temperatures and overly dry or damp atmospheres.

2. Better Aesthetics & Accessibility

A clutter of cables and wires can mean an increasingly sloppy, unsightly mess that can turn off users and service personnel. People tend to enjoy working in neat, organized environments. Prioritizing cable management makes equipment service, offices, or factory floors more approachable.

3. Improved Performance & Efficiency

The best cable management starts with having the best cables, connectors, and systems for the job, using the right materials, lengths, and other specifications. Well-managed cables and wires reduce the odds of disconnections or damage, minimizing downtime and ensuring uninterrupted operations, especially important in equipment, vehicles, factories, data centers, and server rooms.

Proper management optimizes power delivery and performance of your system, by minimizing resistance and voltage drop. It also helps guard against electromagnetic interference (EMI) that can adversely affect audio and video quality, both of which are essential for audio/visual entertainment setups.

5 Cable Management Techniques

In order to enjoy the benefits above, there are a number of best cable management techniques that can be employed. The optimal choices depend on a number of factors including applicable environmental conditions and regulatory compliance.

1. Cable Routing

During installation, cables must be routed in a logical, organized manner which requires careful planning of how to run, arrange, and secure the cables that connect devices and components. This starts with assessing the needs and requirements of the application which includes the devices and components involved, the types and lengths of cable needed, raceway and through-hole dimensions and the environmental factors.

Then a cable routing diagram or schematic — a visual representation of how your cables will run from one point to another, including labels, colors, and measurements — is created whether by drawing it by hand or using software tools, such as AutoCAD or Visio. That design layout acts as a blueprint for installers who use specific techniques, accessories, fixtures, and best practices, such as avoiding sharp bends, vents, fans, crossed cables, and loose loops, to optimize set up while also allowing some slack for adjustments.

2. Overmolding

The process of cable assembly overmolding — when molded PVC or another high-quality polymer is used to surround and encapsulate a cable assembly — adds extra durability, strain relief, and lifespan while delivering a tight fit over cables and connectors. Overmolding also creates a better appearance and overall more polished-looking system, allowing for custom colors, branding, and more efficient labeling. Overmolding is a preferred solution for demanding environments such as those in military, aerospace, vehicle systems, and industrial applications.

3. Labeling & Color-Coding

Labeling cables with printed words, numbers, serial codes, and other information allows for quicker identification and access to specific cables, making maintenance and troubleshooting easier, and saving time and money. Color-coding, which involves assigning specific colors to different wires and cables, also helps installers and maintenance to identify their purpose and function. There are different color codes for North American and international cables.

4. Cable Ties, Clips, & Wraps

There are a number of different fasteners and components used to secure and consolidate cables and wires while also providing additional support by absorbing abrasion with push and pull movements. Cable ties, clips, and wraps are some of the most-utilized ones.

Made of nylon, metallic, or composite materials and available in various sizes, colors, and styles, cable ties, also called zip-ties, are often used to bind and hold multiple electrical cables and wires together. Known for their ease of use and binding strength, cable ties are ubiquitous, finding use in a wide range of other applications.

Cable clips, also referred to as cable clamps, are attached to electrical panels, wire passages, walls, desks, and other surfaces and use pressure to hold cables in place. Great for securing longer runs of cables to walls, cable clips are usually made of plastic or metal and come in a variety of sizes to accommodate different cable types and diameters.

5. Cable Raceways & Trays

Available in a wide array of types, shapes, and materials, cable trays and cable raceways are popular choices for containing cables and creating the safest, most efficient route. Both raceways and trays are long, supportive, and protective channels placed overhead, under-floor, and/or along walls, that run the lengths of the cables. The main difference between trays and raceways is that raceways generally completely enclose and conceal the cables inside them while trays feature open areas for easier access. There are numerous types of cable raceways available in the market, and choosing the correct one for a specific application depends on several factors, such as the type of cabling involved, location, and environmental conditions.

From flat and surface-mounted to rounded and floor-mounted, electrical raceways are long, hollow tunnels specifically designed to house and protect electrical cables and wires. Raceway types include conduits, wireways, and busways. Commonly made of galvanized steel, intermediate metal, electrical metallic tubing (EMT), or polyvinyl chloride (PVC), conduits are hard to access once installed. Wireways are non-circular metal troughs with hinged or removable covers, while busways are enclosed busbar systems that are similar to rigid conduits but feature access points along their length.

Used industrially and commercially, long, open-bottomed cable tray systems are great solutions for running large quantities of power or data cables overhead or under-floor. Also called baskets, trunking, or cable ladders, cable trays are easy to maintain and inspect and are typically less expensive than raceways due to lower material and lower labor costs. Able to fully protect cables and wires, raceways are the preferred choice in harsher environments and underground applications. Raceways also allow for grounding and bonding which offers greater EMI protection.

Proper cable management is essential for optimal functionality, cable performance, ease of maintenance, and overall aesthetics. With over 35 years of experience creating custom wire harnesses, overmolded cable assemblies, and other electrical components, CAI can handle all of your wire and cable needs, including management, regardless of industry or application. Start a conversation with us today about your unique vision.