From Maximizing Lifespans to Enhancing Performance, Overmolding Brings Big Benefits to Cable Assemblies

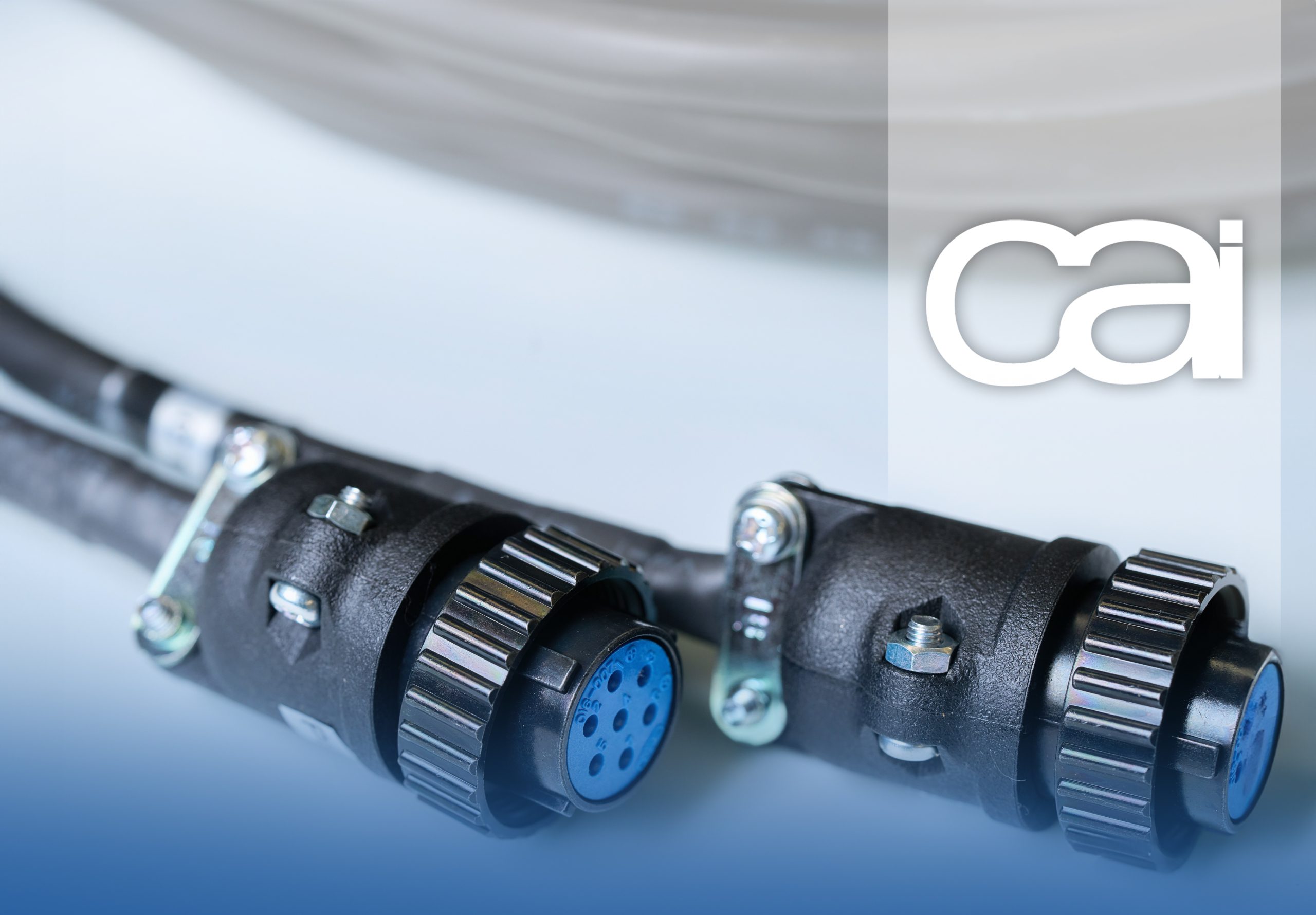

Using sophisticated injection-molding machines, custom overmolding is a popular manufacturing process that, when applied to cable assemblies, adds an extra layer over wires, cables, and components with plastic or rubber to create a single, seamless piece and provide a number of desirable benefits.

During the overmolding process, cable assemblies are placed within mold cavities where hot liquid overlay material is injected at a high degree of pressure. Polyvinyl chloride (PVC), a high-strength thermoplastic, is one of the most popular options due to its excellent durability, moisture resistance, and flexibility. Thermoplastic polyurethane (TPU) is another common choice, known for its fray-resistant and elastic properties. The overmolding fluid adheres to the assembly and is allowed to cool, eventually giving the product an extra layer and the advantages that come with it, including:

1. Longer Life

Depending on its future location and application, the assembly may be forced to withstand a number of destructive forces including water, dust, chemicals, extreme temperatures, human tampering, and so on. Overmolding adds a sealed protective barrier between outside factors and the cables and connectors within, which increases durability and lifespan. It’s especially beneficial for cable assemblies that will be exposed to demanding environments, whether outdoors or on a factory floor.

Furthermore, overmolding enhances strength and flexibility which also ensures a longer life while increasing the assembly’s IP rating (ingress protection). Extra support at connection points helps the cable endure pulling force/tension and provide strain relief. Improving product viability, overmolding helps save money in the long run and avoid the hassle of having to replace assemblies sooner.

2. More Reliable Performance

While durability and reliability are often used synonymously, durability is basically a subset of reliability. From day one, a cable assembly is expected to perform reliably. The more durable something is, the more reliable it will be, day in and day out for years to come. Overmolding delivers a more reliable product in a number of ways.

The enhanced insulation creates a barrier between the conductors and electromagnetic and other types of outside interference, isolating the signals for better performance of both the cable assembly and electrical systems surrounding it. Meanwhile, the added strength provided by overmolding helps guard against shock, vibration, and noise which also improves reliability and durability. In addition, overmolding can reduce the number of steps and over-handling during installation thus helping to save both time and money.

3. Improved Aesthetics

Featuring a more stylish and attractive aesthetic as one seamless piece, overmolding can also bring a softer exterior and enhanced non-slip grip to a cable assembly. Customization also offers a countless number of color, multi-color, color coding, embossed, or printed branding or logo options to not only enhance appearance but also to make identification and installation easier.

From adding logos or brand names to incorporating company colors, custom overmolding lets you truly make the cable assembly your own. The choice to dress a cable assembly so it either stands out or disappears discreetly in its environment is up to each individual and their unique needs.

For over 35 years, CAI has provided cable assembly and wire harness solutions — including overmolding — to countless clients in a wide variety of industries across the globe. We have the experience and skills to handle your manufacturing needs, no matter the volume. Reach out to us today and we’ll help bring your vision to life.