Because CAI is committed to surpassing our customer’s expectations, we don’t just offer harness assemblies. We provide customized cosmetic options for wire harness assemblies that will serve to increase their safety and functionality.

Taking Functionality to a New Level

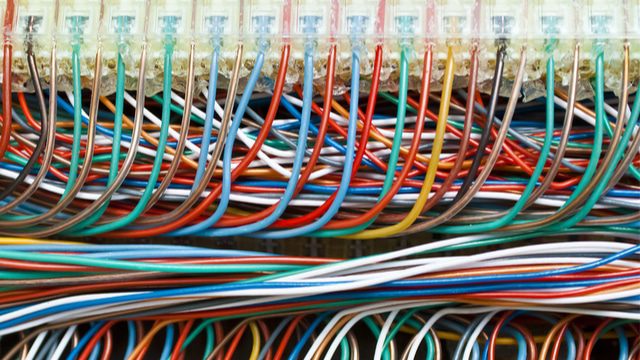

Most of our products may be hidden in the core of precise manufacturing projects, however, our cosmetic options become exceptionally useful during the servicing of those machines and systems. At the forefront of our cosmetic options is overmolding of different colors for your wires. We offer functionality to the servicing side of products by providing colors that help identify those wires. This is a sizable benefit when it comes to the schematic operating of your product design. The color-coding of harness assemblies helps support the assembly of new products, and acts as a sort of road map for where certain wires should be located.

Additional customized cosmetic options for wire harness available include labeling, color matching, color overmolding, branding printing and more.

Taking Safety to a New Level

We value supporting our customers who specialize in constructing safety equipment and offer the convenience of color coding their safety wires for increased recognizability.

Furthermore, we have the ability to custom color exterior or individual wires, standard wires and wire jackets. We understand that your appliances and products require technically precise wiring, usually composed of a specific sequence of wires. We support your company by color-coding your wires in that precise sequence to ensure they are easily identifiable. Our customer-centric culture means we work closely with each customer to ensure your cosmetic options are just what you desire.

What Sets CAI Apart?

CAI provides custom overmolding for wire harness assemblies to enhance the harness’ safety. Providing coloring to your overmoldings add to their safety factor.

How do we infuse color into the overmolding?

The process is similar to injection molding, where various resins are melted and mixed. However, to add certain colors, we inject the resins with color.

CAI also offers printing options as an aesthetic and functional benefit for wire identification, tracing and branding. We can custom overmold a wire with a certain color, then print and match the name brand on the wires and jacket. Another option is printing stripes on wires which aid in necessary tracing and operational service coding.

So, if you’re looking for cosmetic options for wire harness that will increase the functionality of your custom wire harnesses, look no further than CAI.

ABOUT CAI

Since 1986, CAI has delivered custom, high-quality components and wire harness manufacturing to customers across the globe. Offering a personalized approach to every project, CAI partners with customers to create innovative products that exceed industry standards.

Whether we’re creating niche product prototypes or helping a customer turn their idea into a full production run, CAI’s turnkey manufacturing approach delivers a complete product from design to delivery.

CAI’s expertise allows us to produce cost-effective wire harnessing solutions in most any industry or project. We understand the idiosyncrasies of your detailed plans and why following your process is so important. Our personalized, customer-centric process will make sure that your project’s every need is met.

For more information on why our wire harnessing process is the best fit for your project, visit the wire harnessing page on our website or reach out to our team to start work on your custom project.