Today’s Automobiles Rely on an Intricate System of Wire Harnesses

From the engine and dashboard to the headlights and A/C, there’s an intricate electrical wiring system that powers everything in automobiles. With its numerous sprawling branches, it resembles the human body’s central nervous system, and just as we can’t do without our “system,” today’s cars would be useless without the system of wire harnesses inside.

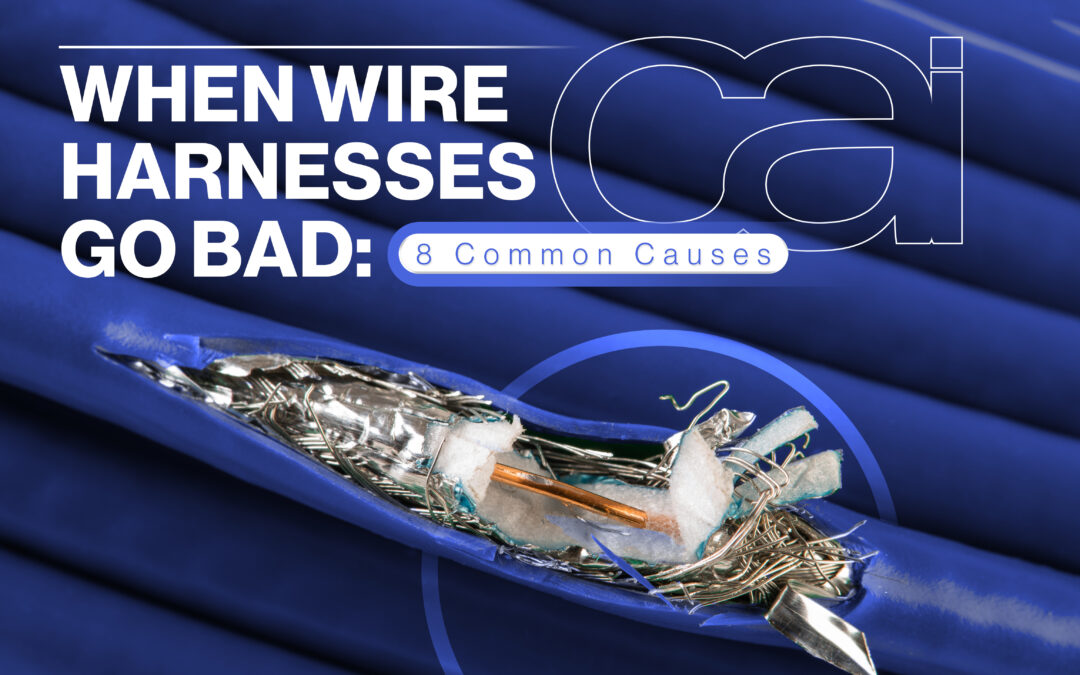

Wire harnesses are bundles of wires, connectors, terminals, and other components connecting and transmitting power and signals to various components, such as sensors, actuators, switches, and electronic control units (ECUs) which drive the connections in a vehicle and support a myriad of features. From performance and safety to comfort and entertainment, wire harnesses ensure the successful, reliable communications necessary for a car to function properly.

Meticulously designed to conform to the contours and confined spaces of a vehicle, wire harnesses help prevent wires from becoming tangled, damaged, and exposed to environmental threats like moisture and heat. They also simplify the installation and maintenance of a vehicle’s many electrical components and help reduce the risk of malfunctions or fires caused by poor wiring.

Obviously, your all-new, state-of-the-art 2024 is going to have a much different and more complex system of wire harnesses than a 1964 model. In fact, today’s automobiles can have up to three miles of wiring and cabling, compared to just a few hundred feet in cars of the ‘50s and ‘60s. Thanks to autonomous driving, AI, and elaborate entertainment/guidance systems, modern, technologically-advanced cars have about 40 split wire harnesses with about 700 connectors and 3,000 wires.

When it comes to wire harnesses in cars, there is no universal solution. A car’s “main harness” is the central unit which powers many other sub-harnesses. These various harnesses cater to different functions and areas within the vehicle, and each model can have a different layout. From optimizing performance and efficiency to ensuring optimal performance, comfort, and safety, these harnesses play diverse and critical roles. Here are some of the common types of wire harnesses used in today’s cars:

Engine Wire Harness

Providing power from the battery to the alternator, fuel injector, ignition coils, spark plugs, and other essential components, the engine harness sends signals between the engine control unit (ECU) and various sensors and actuators to monitor and control the car’s performance and efficiency. It must be able to withstand high temperatures and vibrations as it manages key functions such as fuel and air mixture, ignition timing, and exhaust emissions.

Chassis Wire Harness

The vehicle’s chassis is a pressed-steel frame that acts as a skeleton on which the engine, wheels, transmission, axle assemblies, brakes, and suspension parts are mounted. The car’s body is bolted onto the chassis frame to create a single structural unit. The chassis harness integrates the electrical components responsible for key features attached to the frame, including lighting (e.g turn signals, headlights, and taillights), anti-lock braking systems (ABS) sensors, suspension control modules, and system components.

Body Wire Harness

Intricately routed throughout the car’s body and sometimes into the trunk, the body wire harness provides power and connectivity to essential safety and convenience features and plays a key role in connecting ground points to prevent electrical shorts. This harness has wiring for electrical components in the vehicle’s body, such as the sound system and interior lights.

Door Wire Harness

Designed to flex and bend as the door is opened and closed, a door wire harness must be durable and pliable to facilitate the operation of power windows, door locks, sliding doors, and side mirrors, and prevent wear and tear over time.

Dashboard Wire Harness

Critical to the driver’s operation of the vehicle, the dashboard wire harness connects to the floor harness and powers your dashboard instruments and switches, including the speedometer, warning lights, GPS navigation, and other performance and entertainment features in the vehicle.

Powertrain Wire Harness

The powertrain consists of the engine and the drivetrain, which includes the transmission, axles, driveshaft, differential, and CV joints. Facilitating smooth operation of the powertrain system, the powertrain harness transmits power and signals between the car’s transmission and the engine and its components, including the starter motor, alternator, and battery.

HVAC Wire Harness

Responsible for controlling the climate within a vehicle, the harness for heating, ventilation, & air conditioning (HVAC) connects blower motors, evaporator, condenser A/C compressors, and more to help keep passengers comfortable in the car’s cabin, regardless of the temperature or conditions outside.

Autonomous Driving Harness

Designed and optimized for the specific needs and challenges of autonomous driving, an autonomous wire harness has to handle an incredible amount of data, power, and complexity to ensure optimal reliability, safety, and performance under various driving conditions. Optical harnesses attached to optical sensors assist autonomous driving and monitoring conditions surrounding a car, including people and passing vehicles.

Antenna Harness

Providing both entertainment and added safety features to your car, an antenna harness connects the antenna to the receiver, relaying radio, phone, GPS, and other signals received by the outside antenna.

Electric Vehicle (EV) Harness

Because they require high-voltage cables that carry voltages as high as 1500V, electric vehicles require high-current connectors and more wiring harnesses than conventional automobiles. EV wire harnesses are similar to those for internal combustion engines but feature additional components and complexities while also having to connect to the EV drivetrain. Packed with sensors and actuators that regulate and protect every aspect of the drivetrain, the wire harness system is one of the largest and heaviest components in an EV vehicle.

As car technology advances, the significance and complexity of automotive wiring harnesses continue to increase, requiring evolving engineering and manufacturing processes performed by expert craftsmen.

At CAI, our custom wire harness experts have over 35 years of experience, and automotive wire harnesses are just one of our specialties. We’ve worked with countless businesses across nearly every industry including medical, military, industrial, telecommunications, and more. For all your harness and assembly needs, reach out to us today for a quote or to discuss your unique application and needs.